Problem: Exhaust noise in engine bay an engine lacks power under load.

Solution: I knew there was a leak in the exhaust system and managed to trace it to the engine bay by having a friend block the end of the exhaust pipe (with engine idling) while I checked for the source of the leak.

It appeared to be at the back of the engine. I suspected that the joint between the pipe and the manifold was at fault, and removing the clamp revealed the end of the pipe to be partly worn away.

I had an exhaust specialist weld it up for me and then I refitted it.  The problem was reduced but not eliminated, so I removed the clamp and attempted to reseal the joint with no success. Now that considerable joint sealer had hardened around the pipe, clamp and manifold, I decided to clean the surfaces thoroughly and try sealing it one more time.

The problem was reduced but not eliminated, so I removed the clamp and attempted to reseal the joint with no success. Now that considerable joint sealer had hardened around the pipe, clamp and manifold, I decided to clean the surfaces thoroughly and try sealing it one more time.

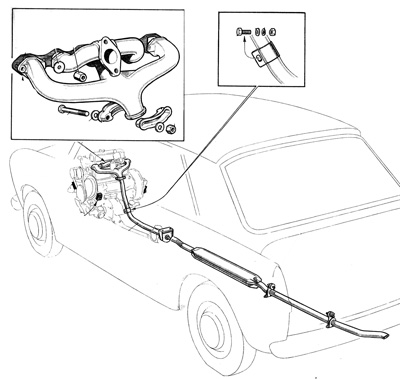

To clean it thoroughly I removed the manifold. Only then did I discover that part of the gasket had worn away at the base of the centre exhaust outlet, hence the leak.

So a $5 gasket and the problem was fixed, engine revving freely again, making that characteristic A-series engine sound and no more holding up traffic on hills!

Problem: Difficulty effectively sealing the exhaust pipe to the manifold.

Solution: This is not one of my favourite jobs partly because it is difficult to reach down the back of the engine, and partly because it is difficult to do it all quickly before the sealant hardens.

Solution: This is not one of my favourite jobs partly because it is difficult to reach down the back of the engine, and partly because it is difficult to do it all quickly before the sealant hardens.

There are two approaches I take now and it depends upon whether the exhaust flange and manifold line up naturally or not.

If they do, I simply loosen the clamp underneath the car that holds the pipe to the transmission and place a trolley jack under the pipe so that when I have the sealant smeared over the joint faces I can operate the jack a few times with my foot as I guide the joint together by hand. With the jack keeping the joint tightly together I can concentrate on attaching the joint clamp accurately and tightly. Then I release the jack and tighten the clamp under the car.

If the manifold and pipe don't line up naturally I loosen the clamp under the car and I loosen the exhaust manifold, ensuring the gasket is not damaged, until I can line the two up. Then I apply the sealant and clamp the joint together tightly. Next I tighten the mainfold bolts very slowly and evenly so as not to disturb the joint. Finally I tighten the clamp underneath the car.