Some essential checks to avoid expensive repairs and inconvenience

There are a couple of areas where deterioration and neglect can lead to a catastrophic failure in an 1100.

One involves the rear suspension and the other involves the driveshafts with rubber inner joints.

The displacer units which provide both spring and damping are quite long lasting and trouble free but if the more vulnerable components are allowed to deteriorate then leaks can begin and ultimately the system will fail. It is quite easy to inspect the front displacers and the hoses/pipes in the engine bay, and to a large extent, the pipes running underneath the floor of the car are readily accessible.

The displacer units which provide both spring and damping are quite long lasting and trouble free but if the more vulnerable components are allowed to deteriorate then leaks can begin and ultimately the system will fail. It is quite easy to inspect the front displacers and the hoses/pipes in the engine bay, and to a large extent, the pipes running underneath the floor of the car are readily accessible.

But the displacers at the rear are a different story.

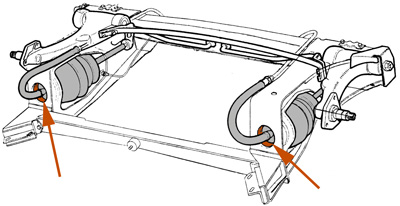

Mounted horizontally within the rear subframe, inspecting them is not all that convenient. This is unfortunate as their location makes inspecting them all the more important as mud and gravel can accumulate where the flexible hose enters the unit. After some time the metal collar on the hose will begin to rust and eventually fluid will begin to leak until the joint fails.

Since the position of the rear displacers is less accessible than the front ones, a failure of a rear displacer is more awkward to fix as it can require the removal and dismantling of the rear subframe - unlike the front displacers.

Since the position of the rear displacers is less accessible than the front ones, a failure of a rear displacer is more awkward to fix as it can require the removal and dismantling of the rear subframe - unlike the front displacers.

It is possible to replace a rear displacer without removing (and dismantling) the subframe - but only if you have access to a Hydrolastic Pump that can induce a vacuum as you need to make the displacer retract up inside itself in order to extract it from the subframe.

The arrows in the diagram above show the area to check and clean.

The rubber universal joints

One major point to check concerns the inner universal

joints where the drive shaft joins the gearbox.

One major point to check concerns the inner universal

joints where the drive shaft joins the gearbox.

All manual transmission models (with the possible exception of some towards the end of production) left the factory fitted with joints of the rubber cross type, however it is not unusual for the rubber type to have been replaced with the more robust all-metal bearing type particularly on 1100 S models.

There are a number of things that can happen with these

if they are not replaced when they show signs of deterioration.

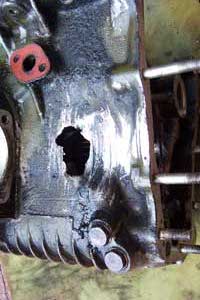

Oil leaks from the engine can cause the rubber to swell and in the case of the joint on the driver's side, it can begin to rub against the side of the gearbox and slowly wear away the soft metal to the point where you have a hole in the side of the gearbox/sump.

If the rubber begins to perish and come away, the metal core of the cross will be forced to flex and move about more than intended and eventually it will snap.

If this happens with the right hand side joint it will almost certainly punch a hole in the gearbox when it eventually snaps.